How Cornell and Corning Inc. decoded a groundbreaking new semiconductor

By Syl Kacapyr

At a small wooden table inside Cornell University’s Sage Hall, three engineers sat to discuss a promising new material with the potential to revolutionize the electronics industry.

It was 2011, and the engineers were discussing a proposed research partnership centered around a new form of indium-gallium-zinc-oxide, or IGZO—a semiconductor with the potential to double the quality of television and smartphone displays using half the energy. That’s according to Michael Thompson, professor of materials science and engineering, who was joined at the meeting by his Cornell colleague Dieter Ast and Peter Bocko, Corning Incorporated’s former chief technology officer.

“It appeared to be a disruptive technology,” said Thompson. At the time, companies were racing to investigate the new material and how it might propel them to the top of the consumer electronics industry.

“We sat down and decided we were going to become equal experts in IGZO,” said Thompson, “understanding the material, understanding the processing restrictions, understanding the impact of impurities.”

The resulting partnership between Cornell and Corning would lift the curtain on this exciting new material and demonstrate why it’s such a promising semiconductor for electronics displays, even today.

A disruptive technology

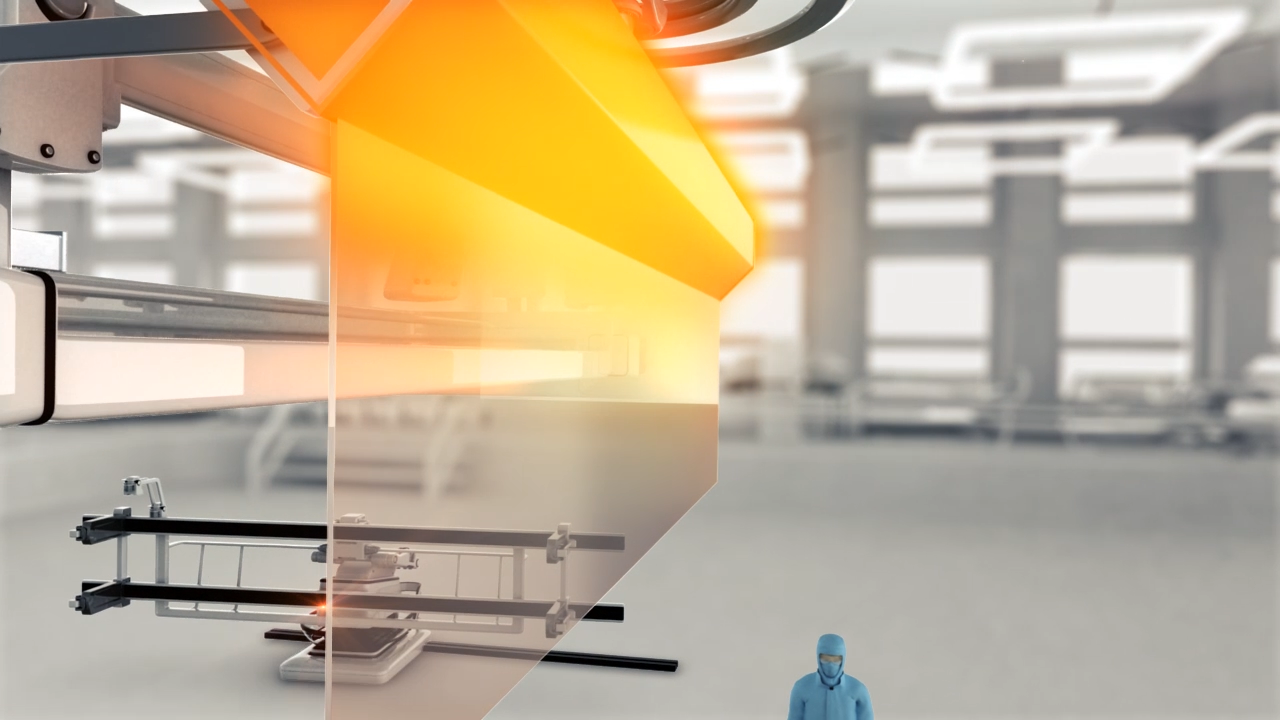

Behind every television, smartphone and computer monitor are thin-film transistors responsible for turning the display’s individual pixels on and off. The quality of the display is only as good as its transistors, which determine the size of the pixels as well as how fast they can change color and even how much power they require.

There are several different materials that manufacturers use for these transistors, each with its own pros and cons. One of the most popular is amorphous silicon, which can cram up to 300 pixels per inch and offers manufacturers a variety of production methods to control for energy efficiency and display quality.

When IGZO thin-film transistors were introduced, they quickly turned heads. IGZO was first synthesized in the mid 1980s, but it wasn’t until 2009 that the Semiconductor Energy Laboratory in Japan introduced a c-axis aligned crystalline version of the material, also known as CAAC-IGZO. Materials scientists found that its unique crystal structure allowed electrons to flow more easily compared to traditional materials like amorphous silicon, meaning the transistors could be smaller and so could the pixels. Early prototype displays were showcasing resolutions of nearly 500 pixels per inch.

Another characteristic of CAAC-IGZO is that it has a low rate of current leakage. This allows its transistors to go longer without refreshing, leading to lower power consumption. And IGZO-based touchscreens are more responsive, an obvious advantage when developing a smartphone display.

A win-win partnership

As world leaders in materials science, Cornell and Corning had a mutual interest in learning more about the new form of IGZO when it was first introduced.

Among other products, Corning—headquartered about 45 miles southwest of Cornell in Corning, N.Y.—manufactures cover glass for mobile devices and precision glass for advanced displays. It had optimized and developed its glass to work flawlessly with amorphous silicon, but in order to meet the requirements of its clients who were taking an interest in IGZO, it needed to better understand the material.

Ray Greene, Ph.D. ’95, manager of the Display Applications Lab at Corning recalls, “All of a sudden it seemed like some of our customers were starting to use it and we really didn’t have a lot of experience with how transistors and processes with those cycles would work with our glass. If the temperature range for an IGZO transistor is different from amorphous, that could have an impact on how well our glass works or doesn’t work.”

For Greene, who earned his doctorate in materials science from Cornell, the partnership was a unique opportunity to work with his alma mater. For Thompson—a renowned materials scientist—the opportunity to research a fascinating and potentially consequential new material was too alluring to pass up. He wondered what properties IGZO could achieve using his expertise in thin-film transistors and high-temperature thermal processing.

“We had pushed as far as we could working with amorphous silicon,” said Thompson, “and here was a new material that was extremely interesting to industry. So the idea that the research had a quick and relatively short-frame applicability in a real industry with real markets was exciting to me. I like basic research, but I’m equally interested as an engineer in carrying it forward toward implementation.”

A formal agreement was reached, and Corning began funding Thompson’s research into IGZO.

A new look at IGZO

When the Semiconductor Energy Laboratory first announced CAAC-IGZO, how the material was synthesized and what its crystalline structure looked like were closely guarded secrets.

“No one had any idea what the deposition conditions should be, what temperature you have to deposit it at or how much oxygen should be present in there,” said Thompson.

_0.jpg)

So his research group went to work. They were eventually able to synthesize the material and identify the characteristics of its unusual crystal structure. The team published the first scientific papers explicitly laying out the conditions that would create the material.

“It was great and the environment was so wonderful,” said Greene, who met with the research team in Bard Hall every Friday afternoon during the project’s five-year duration. “Everybody was just so into it. It was new to them, it was new to us, and the students were just so driven to learn things. It was just a marvelous environment.”

Once the IGZO had been characterized, Corning provided the research team with novel glasses to study the impact on the properties of the IGZO, which resulted in the publishing of seven more scientific papers, according to Thompson.

“We found conditions in which the CAAC-IGZO reported a mobility – a measure of the transistor’s speed – of 75 centimeters-squared per volt-second, compared to typical IGZO materials that are around 10 and amorphous silicon, which is around 1,” said Thompson, who added that the discovery was a record at the time. “In showing what the material was capable of, it opened up the possibility that these kind of mobilities are possible in the system without single crystals.”

In the latter years of the partnership, Thompson’s team was able to reverse engineer some of the first products on the market that were using CAAC-IGZO, developing processes to access and evaluate the thin-film transistors. Corning then used that information to showcase their expertise to clients.

“All the customers we presented that information to basically said ‘wow, we could not do this work ourselves, how did you do it?’” recalls Greene. “That was quite a moment in validating the capabilities of the Cornell team.”

IGZO today

Despite the initial buzz surrounding IGZO, its integration into consumer electronics appears to be much like its predecessors—a slow evolution. That’s according to Greene, who said industry mainstays like amorphous silicon took decades for manufacturers to fully adopt, and that will likely be the case with IGZO. But he added that IGZO is still in play by most major panel makers in some way, shape or form.

Companies like Apple and Sharp are currently using the material in some of their products, with Sharp unveiling new prototypes in recent years, including a virtual reality display screen containing over 1,000 pixels per inch.

And although the research partnership involving IGZO has formally ended for Cornell and Corning, both are still reaping the rewards. Thompson said his interest in IGZO was one of the inspirations for a new project that could potentially help produce a slew of buzzworthy new materials.

“IGZO is a remarkably complex material system,” said Thompson. “Being able to do hundreds of thousands of ratios of its elements, how do you search that to understand what the outcome will be?”

The answer could be “Scientific Autonomous Reasoning Agent: Integrating Materials Theory, Experiment and Computation,” which is the name of a new research project in which AI-based algorithms could help identify the conditions under which new materials perform best. One target goal of the project, according to Thompson, is to find a semiconductor with high mobility and low sensitivity to a deleterious materials problem called “negative bias temperature instability,” an instability that causes color fade in smartphone displays as they age.

And as for Corning, Greene said: “I find myself, at least a couple times a year, applying some of the things I learned from that project. Our base understanding of customer processes of IGZOs and their ranges were later validated commercially with costumers and are still true.”