Earth Source Heat - Cornell Eyes Engineering Challenge to Heat its Campus and Beyond

By Syl Kacapyr

When asking Cornell alumni about some of their more infamous memories, a likely answer is the arduous winter trek up Libe Slope. Not wanting to arrive late to class, students can be seen climbing the small, but steep, hill with the determination of early 19th century explorers attempting to reach the North Pole.

But unlike those rugged explorers who first navigated the arctic, students enjoy a much more reasonable winter and can quickly find warmth inside the confines of a classroom. Ensuring the luxury of warmth throughout Cornell’s 745-acre campus comes at a cost, as it does for any resident of a seasonal climate. The university’s annual energy bill is approximately $42 million, a large fraction of which pays for heating-related expenses. The heat expended by campus leaves behind an annual footprint of roughly 110,000 metric tons of carbon dioxide.

Recognizing that business as usual would continue to bear these costs, former university President David Skorton committed Cornell to becoming a carbon neutral campus. In 2009 he launched the Climate Action Plan, which evolved through the years to ultimately proclaim the ambitious goal of making the Ithaca campus carbon neutral by 2035.

Since that time, Cornell has decommissioned its coal- powered boilers, constructed several solar farms, committed to purchase wind power and met most of its cooling needs using renewable cold water from the depths of Cayuga Lake. This, combined with energy conservation efforts, has reduced Cornell’s carbon emissions by more than 30 percent. But to become carbon neutral, it’s become clear that Cornell must find a powerful, yet cheap and renewable source of heat for its campus. So what does an institution full of engineers, scientists and thought leaders do when a practical solution to a challenge doesn’t exist? It creates it.

In September, the university announced a project called Earth Source Heat. The idea behind the project is to tap the earth’s vast heat reservoir using an enhanced-geothermal system. Unlike traditional geothermal systems, Earth Source Heat would be best optimized by reaching hot basement rock—metamorphic or igneous rock that is 200- to 300-degrees Fahrenheit—sitting up to 5 kilometers below campus. To reach that depth, extract the clean, renewable heat and then distribute it throughout the campus would require a feat of engineering that has yet to be achieved in the U.S. It would require breaking the rules to challenge conventional thought about how and where such geothermal systems can be deployed.

The stakes are high. If successful, Cornell would all but eliminate the use of fossil-fuels to heat its campus. But the ultimate goal is much larger than that. Success would mean demonstrating a new energy solution that could be adopted by other communities in the U.S. and beyond.

Geothermal Today

To understand the technical and economic challenges of engineering the geothermal system envisioned by Cornell, one must also understand why there has been little precedent.

Facilities leaders at Cornell first began conceiving of Earth Source Heat, or at least how the university might take advantage of geothermal energy at a large scale, nearly a decade ago following the 2007 release of the landmark report “The Future of Geothermal Energy.” The report, chaired by Jeff Tester, director of the Cornell Energy Institute who was an MIT faculty member at the time, was a comprehensive assessment of the potential for geothermal energy to become a major energy source for the U.S.

A major finding of the report is that geothermal energy has the potential to add about 10 gigawatts of commercial electric- generating capacity to the U.S., representing about 1 percent of the country’s overall capacity today. That’s if the energy is generated from traditional hydrothermal systems that require the presence of fluid, heat and permeable rock. But if enhanced- geothermal systems were used to extract heat from harder-to- reach basement rock, the U.S. could gain over 100 gigawatts of capacity within 50 years, representing an astounding 10 percent of the country’s electric capacity. Unlike hydrothermal systems, enhanced-geothermal systems don’t require naturally-occurring water and rock permeability because those elements can be engineered, geographically broadening where geothermal energy can be deployed.

The report garnered interest from energy leaders and policy makers. Geothermal technology companies like AltaRock Energy began to sprout. At the same time, countries like Australia were already beginning to implement enhanced- geothermal systems. “So it was really a period of international enlightenment for this. Even Google and other companies like Kleiner Perkins were putting money into research,” said Tester, who is also the Croll Professor of Sustainable Energy Systems in the Robert F. Smith School of Chemical and Biomolecular Engineering.

But U.S. enthusiasm for the renewable energy source soon began to wane. There wasn’t any one place to cast blame, according to Tester. Relatively cheap fossil fuels, competing renewable technologies and an economic recession, among other diversions, quelled interest in geothermal research and development despite the implications for energy security and the environment.

Today, a small handful of enhanced-geothermal systems exist in the U.S., all of which are found in western states where geological conditions are more favorable and basement rock is easier to access. Those systems are serving mostly as experimental, demonstration projects that focus on using the earth’s heat to produce electricity, as opposed to “direct-use heat,” in which it’s applied directly for use in a heating system.

“We should have much more of a national sense of urgency of doing this. The issues of climate change are becoming so apparent now that we’ve got to get started in a serious way,” said Tester, who was motivated to come to Cornell, in part, by the opportunity to develop a geothermal district energy system for campus.

Tester, along with his students and faculty colleagues, has continued to publish work highlighting the potential of geothermal energy through a series of reports examining direct- use heating. A recent study authored by Koenraad Beckers ’16 Ph.D., a former student of Tester’s who now works for the National Renewable Energy Laboratory, demonstrates a new model for quantifying the technical and economic direct-use potential for the U.S. Tester says the research represents an interesting shift in geothermal interest, away from the inherent limitations of electricity production. “To really make enhanced geothermal work economically, particularly with the low-cost, affordable fuels we have now like natural gas, we’re going to have to look at ways in which we can use geothermal heat directly,” he said.

Envisioning the System

The challenge of harvesting heat submerged deep within the earth and transporting it to more than 250 buildings on campus is exacerbated by the fact that no existing geothermal systems address Cornell’s precise geological circumstance and heating goals. But faculty and facilities engineers do have a conceptual vision of Earth Source Heat.

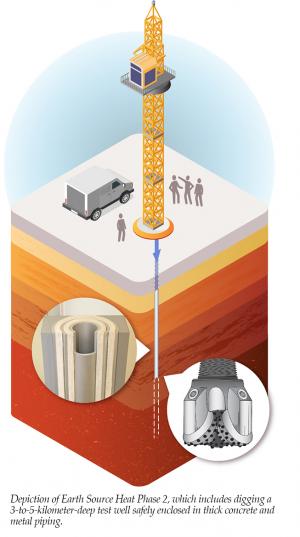

To reach the underground hot rock and extract heat, a pair of wells would be drilled. Each well would have a sufficient diameter to accommodate 40 to 80 liters per second of water flow, leaving enough room for thick concrete casing and metal piping. Until more is determined about the rock formations below Cornell, it’s not known exactly how deep the wells would need to be. Reaching the desired temperature range would likely require delving 3 to 5 kilometers, or 1.9 to 3.1 miles, below the surface.

To reach the underground hot rock and extract heat, a pair of wells would be drilled. Each well would have a sufficient diameter to accommodate 40 to 80 liters per second of water flow, leaving enough room for thick concrete casing and metal piping. Until more is determined about the rock formations below Cornell, it’s not known exactly how deep the wells would need to be. Reaching the desired temperature range would likely require delving 3 to 5 kilometers, or 1.9 to 3.1 miles, below the surface.

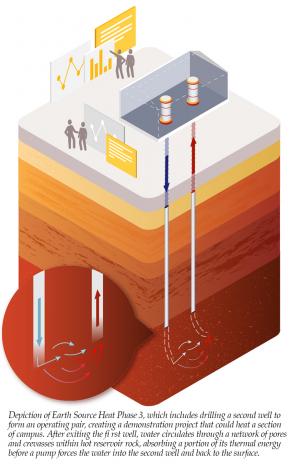

Water would flow down the first well into a deep reservoir, circulating through a network of pores and crevasses within hot reservoir rock and absorbing a portion of its thermal energy. The water would then be pumped back to the surface through the second well.

Once at the surface, the heated water would enter a heat exchanger—essentially two chambers separated by a thin layer of steel—that transfers heat from the geothermal fluid to water contained in a second, closed-loop system that would distribute the supply of heat to a network of campus buildings. A facility would safely house the wells, heat exchangers and most other visible components of the system.

The single well pair would only be capable of heating a section of campus, so approximately four to six well pairs would be required to heat the entire campus. A formal siting hasn’t been conducted, but criteria for the location of each well pair includes distance from private land and adjacency to the designated area of campus it would serve.

Earth Source Heat resembles Cornell’s existing system in that a centralized source of heat supplies the entire campus. The current system relies on the university’s Combined Heat and Power Plant, where natural gas powers two large combustion turbines that produce the campus’s electricity supply. Waste heat from the turbines is collected by steam generators and the steam is distributed throughout campus. “Steam is not a modern and efficient way to distribute heat in a district energy system,” said Robert Bland ’74, M.S. ’80, M.B.A. ‘96, associate vice president for energy and sustainability in Cornell’s division of Infrastructure, Properties and Planning. “About 20 percent of energy is lost to the ground, even through a well maintained and insulated system.”

Water used in the Earth Source Heat system would maintain more of that energy. The desired temperature engineers hope to reach underground is at least 200-degrees Fahrenheit, although research will reveal the full range of temperatures attainable under campus, and at what depths they occur, so that a cost-benefit analysis can be done to determine the best temperature to use in the system.

The cost of converting the current distribution system into one compatible with Earth Source Heat is estimated at $200 million, but the existing pipe routes and potentially some of the power plant could be utilized. “The real advantage is the buildings are already set up for an external source of heat,” said Bland, adding that most buildings would only require modifications as opposed to complete revamps.

Energy Sources

An exciting vision for Earth Source Heat is its cascading uses, according to Bland, meaning the heated water produced by the system could deliver financial and environmental benefits beyond heated buildings. “So the idea is it comes out of the ground, heats buildings, then flows at a lower temperature to heat a greenhouse or heat-dry biomass,” said Bland.

The prospect of being able to dry biomass materials such as willow and switch grass plays into one of the recommendations for the Earth Source Heat system, which is to supplement it with a biomass gasification facility. The biomass facility would serve as an additional heat source during winter cold snaps when the increased demand for heat can’t be fully satisfied by the geothermal system. Bland says heating the entire campus with biomass isn’t feasible, but for managing peak load on the system, “it’s a cheaper alternative to building a relatively expensive well pair that would just be used for a few days a year.”

The idea of adding not one, but two new sustainable energy sources to Cornell’s repertoire is exciting for many, but especially for Bland, who has dedicated much of his 30-year career at Cornell to keeping the university at the forefront of energy sustainability. After graduating from Cornell with a chemical engineering degree, Bland worked in the energy industry before returning to Cornell to research alternative fuels, specifically waste cellulosic ethanol biofuels. He has since brought his passion for energy and the environment to the division of Infrastructure, Properties and Planning, where he’s been instrumental in bringing renewable energy sources to Cornell, including the Lake Source Cooling system that inspired Earth Source Heat.

Lake Source Cooling pumps water from the depths of Cayuga Lake—where temperatures remain around 40-degrees Fahrenheit year-round—to a heat-exchange facility that then pumps cold water to campus, where it cools buildings and lab equipment. The system went online in 2000, replacing the university’s less efficient refrigeration-based water chillers and reducing campus electricity use by more than 10 percent. In its 17 years of operation, Lake Source Cooling has flawlessly worked to reduce Cornell’s carbon footprint while also serving as an award-winning model of innovative energy technology.

Bland hopes the same radical ingenuity that produced Lake Source Cooling can also make Earth Source Heat a reality. “I really believe we have a climate crisis and I’m personally motivated and passionate about creating a carbon neutral campus,” said Bland. “It’s great that Cornell can do this not only to reduce our own emissions, but also to demonstrate to the world a new use for this technology.”

What Lies Below

The precise design of the Earth Source Heat system is contingent upon the geology that lies beneath Cornell, particularly how deep, how hot and how permeable the rock formations are. “We don’t quite know what we’re going to find when we drill down 3, 4, 5 kilometers. We have earth scientists, geophysicists and a variety of people involved in studying what that is going to look like,” said Todd Cowen, a professor of civil and environmental engineering, the Kathy Dwyer Marble and Curt Marble Faculty Director for Energy at Cornell’s David R. Atkinson Center for a Sustainable Future, and a member of the Earth Source Heat Executive Steering Team.

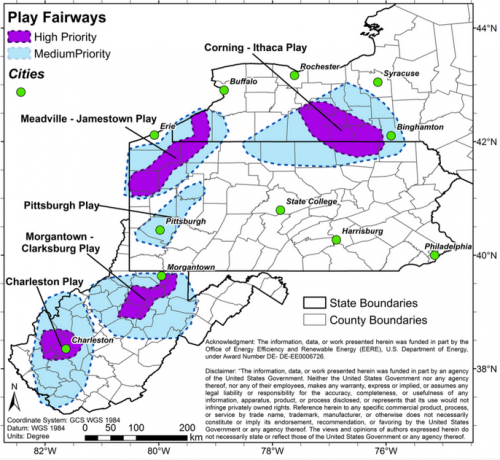

There are early clues as to what those scientists will find thanks to a 2016 Cornell study that analyzed the subsurface rock properties of a large portion of the Appalachian Basin. Faculty and graduate students from three different Cornell Engineering departments rigorously pored through data generated by the fossil fuel industry, examining nearly 40,000 drilling locations throughout much of New York, Pennsylvania and West Virginia. Informed by oil- and gas-well logs, the scientists were able to map which regions were most likely favorable for direct- use geothermal energy.

From the perspective of Cornell’s Earth Source Heat plans, the most important factor analyzed by the researchers was natural reservoir quality. “We were looking for rocks that had natural pore space. You want rocks that have holes in which hot water can be stored. You also want those pores to be interconnected by flow paths,” said Teresa Jordan, the J. Preston Levis Professor of Engineering and principal investigator for the study. These reservoirs can include anything from sedimentary rock layers that have permeable zones to basement rock in which water would more likely flow along fractures or old fault zones.

Such permeability needs to be well tuned in a geothermal system: it should allow water to move slowly enough to absorb the earth’s heat, yet fast enough to be pumped to the surface. The larger the reservoir, the larger the water flow and amount of heat that can be delivered.

“The Appalachian Basin has a small set of locations where we think natural flow will suffice for a Cornell-type system,” said Jordan, noting that the Elmira-Corning region of New York provides attractive conditions. “Gas fields there are proven to be able to flow at high rates. Gas isn’t the same as geothermal fluid, but if you’re in a good position to flow the gas, the odds are improved that you’re in a good position to flow the water as well,” added Jordan.

Sitting directly between Elmira and other locations where fossil fuel companies discovered favorable rock types is Cornell. But it’s still unknown if the Ithaca area shares the same reservoir quality because those companies never explored it, leaving the research team with little data to analyze.

“It’s entirely plausible that sitting right under campus could be the rocks with the pore spaces that are just as good as the ones in Corning. Maybe there are horizons in the rock at around 2.6 kilometers below us which would be happy to deliver water to us if we started pumping,” said Jordan, noting that such a dream scenario could allow Cornell to move forward with the Earth Source Heat project without the challenge of artificially engineering suitable permeability conditions.

A Closer Look

A first step toward gathering better geological data for the Ithaca area began in 2015 when—supported by an Atkinson Center Academic Venture Fund—Cornell engineers buried 15 seismometers across the campus to measure seismic activity over the course of a year.

Data from the Intraplate Tectonics Monitoring Project—led by Larry Brown, the Sidney Kaufman Professor in Geophysics, and Katie Keranen, assistant professor of earth and atmospheric sciences—is still being analyzed, but will eventually shape the engineering behind Earth Source Heat by helping to determine the subsurface conditions that will affect design options. Those conditions include rock permeability, response to water being pumped through, and how that water flow could be artificially enhanced.

Early analysis of the data has revealed spikes in activity, but according to Brown, it’s unclear if those spikes are related to earthquakes. “One spike looks like we picked up airplanes landing at the airport, for example. We also expect to detect some of the blasting going on relative to the area salt mines.”

The sensitivity of the equipment is key because the ability to detect small earthquakes that aren’t felt by people on the surface could indicate that the area has an active fault, something that would, under certain conditions, respond poorly to a geothermal system circulating water underground. But so far there’s no reason to believe that’s the case, especially given Ithaca’s lack of earthquake history. Still, more analysis needs to be conducted.

Aside from background seismicity, the project recorded global earthquakes that were detected locally. “That data will tell us something about how the ground here responds to earthquake waves. We may get very different responses if we’re sitting on a thick layer of glacial deposits versus sitting closer to bedrock,” said Brown.

These data are also important because they could give researchers a better idea of where quality reservoirs or rock layers prime for geothermal are located below campus. This would allow engineers to choose locations to conduct more sophisticated experiments such as active seismic surveys, in which vibroseis trucks send vibrations into the ground, resulting in an acoustic, three-dimensional views of exactly what lies below.

All of the data being gathered by the research team are being made public through a website that, once launched, will also share real-time seismic data for the Ithaca area. In the meantime, Brown invites the public to view the analog seismograph station located in Cornell’s Snee Hall.

“This is a great opportunity to let the community in on what we’re studying and to help them understand the distinction between induced seismic activity that is dangerous and induced seismic activity which is actually just signals that help us to avoid earthquakes,” said Brown, referring to seismic surveys. Once Earth Source Heat moves into the installation phase, small tremors may also occur during the well-drilling process. Scientists can use this seismic data in the same way, including to track how fluid is flowing through the subsurface. “Think of it like receiving an X-ray,” said Brown, analogizing seismic imaging to how a doctor would image bones in the human body.

Building a Team

Understanding the geology below Cornell’s campus and then engineering a system based on those findings will be challenging, “but the reality is we have people that are building businesses on these technologies already. The technical challenges are surmountable,” said Cowen. “The greatest challenge we’re going to face is really one of the traditional challenges we always see in energy transformations, and that is engaging our community, listening to and addressing their concerns, and working with them to develop a way forward.”

In October, the university released a report titled “Options for Achieving a Carbon Neutral Campus by 2035: Analysis

of Solutions.” In it, Cornell’s Senior Leaders Climate Action Group stressed the importance of pursuing energy solutions in partnership with local, national and international entities. This includes local community members, Cornell alumni, private businesses, foundations and government partners interested in helping to move Earth Source Heat and other sustainability initiatives forward.

In October, the university released a report titled “Options for Achieving a Carbon Neutral Campus by 2035: Analysis

of Solutions.” In it, Cornell’s Senior Leaders Climate Action Group stressed the importance of pursuing energy solutions in partnership with local, national and international entities. This includes local community members, Cornell alumni, private businesses, foundations and government partners interested in helping to move Earth Source Heat and other sustainability initiatives forward.

“Our aim is to not only work toward carbon neutrality on campus, but to pioneer new technologies that communities large and small can implement,” said Lance Collins, the Joseph Silbert Dean of Cornell Engineering and co-chair of the action group. “Everyone should have a stake in this because we’re all facing the same need for new energy solutions.”

Cornell faculty, staff and students are especially called upon to help move the university’s Climate Action Plan forward. While Earth Source Heat and other renewable-energy projects are highlighted as key recommendations for achieving carbon neutrality, the report also lauds a multi-level approach that includes reducing the overall demand for energy on campus.

“Over the past decade, our Ithaca campus has grown by more than 2 million square feet, but energy consumption has actually decreased thanks to improving building-energy efficiency and the Energy Conservation Initiative driven by ingenuity and engagement from faculty, staff and students who share the urgency to make a difference on campus,” said Provost Michael Kotlikoff while discussing the report with the Cornell Chronicle. Other programs such as Think Big, Live Green and Campus Climate Literacy Engagement are noted in the report as having produced significant energy savings.

University leaders have hosted open community forums to discuss the report and the Earth Source Heat project. More are being planned as Cornell continues to share the risks and rewards of its Climate Action Plan, including the costs associated with becoming carbon neutral. While pursuing Earth Source Heat, wind-water-solar projects and a biomass facility could reduce Cornell’s annual operating costs by as much as $19 million, according to the report, capital costs could reach $700 million.

Cowen believes that must be weighed against the cost of doing nothing. “We have a challenge as we face transitions, where we look and say, ‘I don’t want a wind farm because that affects my viewshed. Or I’m worried about what that does,’” said Cowen. “What people don’t think about is by doing nothing, you’re not making a decision to do nothing. You’re making a decision to do the status quo.”

Next Steps

While much of Cornell’s Climate Action Plan has already been set in motion, its key component—Earth Source Heat—is far from shovel ready. Research to determine exactly what the geology under Ithaca’s East Hill looks like will continue along with other experiments to determine the feasibility of engineering a safe and economical enhanced-geothermal system.

“The very first phase is really a preparatory phase to do the permitting, siting, to figure out where we would place this and to do the community outreach,” said Collins. “We need to make sure that the community is supportive and that the permits are going to be able to come forward.” Collins says the first phase will also examine system design at a baseline level.

“The very first phase is really a preparatory phase to do the permitting, siting, to figure out where we would place this and to do the community outreach,” said Collins. “We need to make sure that the community is supportive and that the permits are going to be able to come forward.” Collins says the first phase will also examine system design at a baseline level.

Within the next two years, Cornell hopes to move into phase two with the installation of a single test well that will provide the best understanding yet of the ground beneath campus and what a full-scale system might require. “But at the moment, the funding doesn’t exist. So we’re in the process of trying to build the fund to initiate,” Collins added. “It’s going to be like that peg solution, where each time you get one thing to happen, it allows you to reach a little bit higher on the next one.” If the test well produces viable results, a third phase would seek to install an adjacent well and heat- exchange facility, creating a small-scale demonstration project that could heat multiple buildings within a section of campus. It’s expected to take about six years to complete all three phases and if successful, a full-scale project could then be implemented over the next 10 years.

“It’s the seamless connection between students, faculty and the facilities people that can actually implement what we learn from the experiments and from the research that we’re doing into a full-scale demonstration,” said Collins, describing the university as a “living laboratory” that often employs a research-to-application model. “It’s really unique and there are few places in the world that can pull all of that off, and so it makes me very proud to see what we’re going to be able to do here at Cornell.”

The path to Earth Source Heat is a long, steep hill to climb—one that makes a snow-covered Libe Slope seem not as daunting. But Libe Slope does provide some foresight. At its peak is the Arts Quad where a statue stands of the university’s founder, Ezra Cornell—an engineer himself who once envisioned how a technology might one day change the world.