Big changes are underway in Upson Hall as the Sibley School of Mechanical and Aerospace Engineering embarks on a major transformation of its machine shop into the cutting-edge Autodesk Design and Make Space – an ambitious reimagining made possible through a $4.3 million gift from Autodesk, one of the world’s leading software companies.

The investment, championed by alumni and Autodesk executives Jeff Kinder ’89 and Amy Bunszel ’89 reflects a shared commitment to preparing the next generation of engineers, designers and makers for a rapidly evolving technological landscape.

Autodesk contributed $2 million to Cornell Engineering and $2 million to the College of Architecture, Art and Planning to name and update key “design and make” facilities, along with $150,000 in discretionary funds for each college. For Cornell Engineering – and especially the Sibley School – this support is already reshaping the student experience.

Cornell Engineering’s new Autodesk Design and Make Space will be in Upson Hall. David Erickson, S.C. Thomas Sze Director of the Sibley School, said, “This gift from Autodesk allows us to create the fabrication facility of the future and make it a cornerstone of the Sibley School experience – a training ground for future engineers to master the hands on manufacturing skills that will set them apart.”

Phase One: A reimagined future

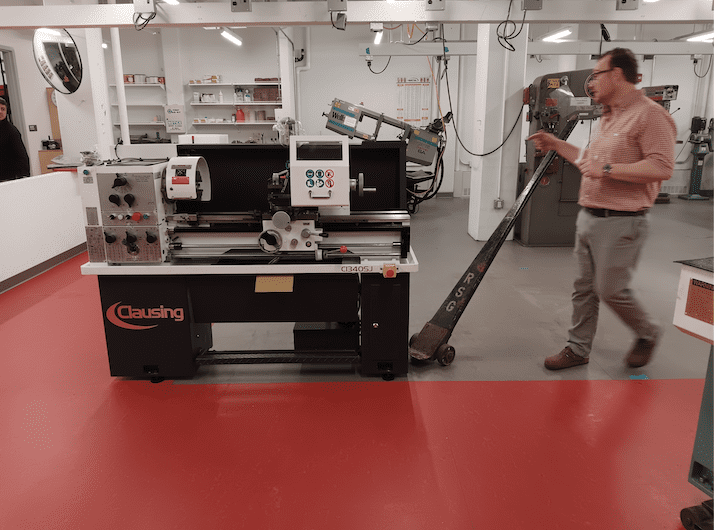

This past summer marked the first major steps in the multi-year buildout. Under the leadership of David Hartino, director of instructional labs, and Vincent Chicone, director of the Autodesk space, the team installed new lathes, repaired existing mills and saws, and began reconfiguring the shop for a dramatically expanded set of capabilities. The team also produced a suite of new instructional videos introducing students to the space and providing guidance on safe and effective machine use, with more to come as additional equipment comes online.

Among the impressive new additions, the school welcomed a state-of-the-art 5-axis Haas CNC machine and new Haas “Mini Mills,” significantly strengthening CNC training and fabrication capacity. In the metrology lab, a Keyence Coordinate Measuring Machine and a Keyence 3D scanner are now fully operational, with student training sessions launching soon.

What comes next?

While the early progress is substantial, the Sibley School has its sights set even higher. Over the next year and a half, the team will continue construction upgrades, commission additional machines, and expand training programs. If all goes according to plan, every new system will be fully online by the end of the spring 2026 semester.

Future additions promise to broaden what students can design, test, measure and build. Planned equipment includes an Omax 5555 JetMachining Center for advanced 3D multi-axis cutting; a Kern 500w Laser Cell capable of slicing half-inch steel with precision; new CNC routers for rapid foam, wood, acrylic and carbon-fiber processing, and two Stratasys 3D printers – including the aerospace-grade Fortus 450 and the high-precision DPL Origin Two to support rapid mold-making and on-demand manufacturing.

None of this progress would be possible without the generosity of Autodesk, the Sibley School Advisory Council, Cornell Engineering and an enthusiastic network of alumni. Their support is helping ensure that students gain access to the same cutting-edge tools and technologies shaping industry today, and will be poised to lead in the fields of tomorrow. As the Autodesk Design and Make Space continues to take shape, one thing is clear: Sibley students are entering a new era of creativity, capability and innovation. Stay tuned, the best is yet to come.