Giancarlo D’Orazio, doctoral student in the Sibley School of Mechanical and Aerospace Engineering, was recently awarded the Cornell NanoScale Science and Technology Facility (CNF) Fellowship.

The CNF Fellowship is intended for Cornell graduate students, who are also CNF users, and supplements their graduate research assistantships. D’Orazio will be characterizing equipment at CNF, as well as researching applications and matching them with other capabilities at the facility.

“For instance, you could print an intricate micron-scale structure, then use the atomic layer deposition machine to apply a thin film or series of films to the surface of your structure and create a small-scale battery,” says D’Orazio. “Or in our case, perhaps an electrochemical cell.”

D’Orazio is a member of the Sobhani Lab, led by Sadaf Sobhani, assistant professor in the Sibley School of Mechanical and Aerospace Engineering. The lab is focused on combustion and is contributing scientific innovations that enable high-efficiency, low-emission and robust energy management technologies.

D’Orazio is working on two projects in the lab – CO2 Reduction Reactors (CO2RR) and Porous Media Combustion (PMC). “They’re related in that they are both centered about reducing emissions (like CO2 and NOx) and are both relying heavily on additive manufacturing to do so,” says D’Orazio.

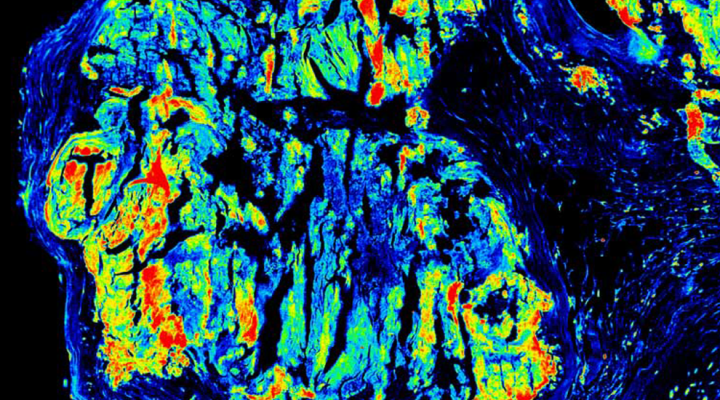

In the CO2RR project, D’Orazio and his fellow researchers are making very small lattice structures on a specialized printer called the Nanoscribe Photonic Professional GT2, one of the many instruments available at CNF. The Nanoscribe is a state of the art two-photon polymerization volumetric maskless printer that can print nanometer scale features in resin.

A CO2 Reduction Reactor is a type of electrochemical cell in which CO2 is introduced and converted into another compound. The lattices are similar to a gas diffusion layer in a CO2 Reduction Reactor, a device that takes CO2 and converts it to another compound for sequestration. This means a CO2 Reduction Reactor can be used to reduce atmospheric CO2 by converting what’s in the air to ethanol for instance or another organic compound.

In the PMC project, D’Orazio and his fellow researchers are printing and testing Porous Media Burners. These burners can combust fuel more efficiently in fuel-lean conditions than a traditional open flame, usually yielding fewer NOx emissions. The porous media, which is traditionally a ceramic foam, heats up from the combustion, transfers heat into the combustion gases, preheating them. In the lab the team is making porous media by 3D printing formula driven lattices – allowing them to simulate the behavior of each burner before its tested.

The collaborative nature in the Sibley School is one of the things D’Orazio appreciates the most about his graduate experience.

“I’ve found that in the department there is a great collaborative spirit, so other labs and professors have been really interested in allowing our lab to borrow their time, or equipment, or materials,” says D’Orazio. “This extends to other groups, like CNF and CCMR, who are all working together to do great things.”

After completing his Ph.D., D’Orazio hopes to continue doing research at somewhere like NASA. “They’re currently doing a lot of work on additive manufacturing at their Marshall Space Flight Center for instance, which is what I’d like to keep working on once I graduate,” says D’Orazio.